News

Find out what’s new with Photron!

Customer Stories

Free White Papers

Biology and Biomechanics

Combustion and Gases

Fluidics and Microfluidics

- From an elongated cavity to funnel by the impact of a drop train. Read

- Ultrafast imaging method to measure surface tension and viscosity of inkjet‑printed droplets in flight. Read

- Popup Height and the Dynamics of Rising Buoyant Spheres. Read

- Measurement of a laser-induced underwater shock wave by the optical-flow-based background-oriented schlieren technique. Read

Materials Testing

- Experimental Study of the Effectiveness of Sacrificial Cladding Using Polymeric Foams as crushable Core with a Simply Supported Steel Beam. Read

- Experimental studies on the deformation and rupture of thin metal plates subject to underwater shock wave loading Read

- Shooting rubber bands: dynamic buckling in unconstrained elastic ribbons. Read

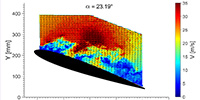

DIC and PIV

- Time-Resolved PIV Measurements and Turbulence Characteristics of Flow Inside and Open-Cell Metal Foam. Read

- Phase Image-based Particle Tracking Velocimetry using Digital Holographic Microscopy. Read

- Tomographic Particle-Image Velocimetry Analysis of the Influence of Artificially Introduced Sound Waves on Transonic Buffet Flow. Read

Other

- Can jet engine tests help COVID-19 research? Read

Welcome to the Photron Family!

What our customers are saying…

- Oxford Engineering

- Cranfield Impact Centre

- Oval Medical

- London Metropolitan Police

- Carnegie Mellon University

- University of Cambridge

- Reamda Ltd.

Two high speed cameras (Photron FASTCAM SA5, Photron Ltd) are being used to study dynamic failure of carbon epoxy composites undergoing ballistic impact testing on a gas gun. The out of plane deformation and the failure patterns of the target area, were observed and recorded by synchronized cameras with stereo-DIC setup. With great flexibility and reliability, Photron cameras have provided us with the ability to capture high quality images of composites under impact events. In addition, Photron FASTCAM Analysis (PFA) software enables the easy and accurate calculation of real-time bullet velocity during the impact.

> Impact and Shock Mechanics Laboratory (ISML), University of Oxford, UK

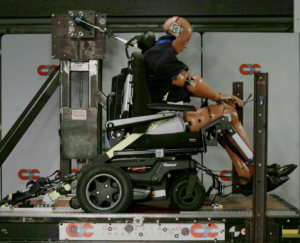

Cranfield Impact Center just completed a series of crash test of a wheelchair/occupant and tie down restraint system for in-vehicle use. The successful tests were conducted to the ISO 7176 Part 19 standard.

A requirement of the standard is that the tracking of the occupant is captured to determine the maximum trajectories of various body parts. The crash test dummy used by CIC used Photron 6D Markers which provided reliable and accurate data. Used in conjunction with Photron, high-speed cameras the data was generated with a high resolution. CIC Manager Dr. Jim Watson commented “The technical support from Photron was exceptional, in assisting us with the generation of the high-speed images.”

At Oval Medical we endeavour to understand every detail of our novel auto-injector designs. Having performed a comprehensive selection process for a high-speed camera application, it was clear that Photron was the standout, not just on overall performance but quality of service. Recently, Tim Nicholls from Photron UK ‘popped over’ and spent a day helping us with a special application to use the camera with another top end piece of kit, our Instron force tester. This enables us to run the camera optimally and provides a powerful tool to align test profiles with high-speed imaging. The AX100 has provided invaluable R&D insights and Photron UK a firstclass service.

> James Cobb, Test Engineer, Oval Medical Technologies

We have used the Photron Ltd high speed cameras for many years to support our ballistic trials. Without the excellent quality of these cameras we would not be able to accurately evaluate ammunition performance through barriers and the terminal performance of bullets within the gelatin blocks. The clarity of imagery both from video files and the still pictures that we can take from these is superb. Evidenced obtained through the use of the Photron camera has allowed us to evolve police ammunition and also support manufacturers with feedback on their products.

The support from Photron Ltd is excellent with both remote and in field support never being too much trouble and allows us to get the most from the camera system.

> Chief Inspector, Metropolitan Police.

As an additive manufacturing researcher, I am often trying to capture images of small phenomena that chnage brightness quickly. The AX200 has worked really well for me. The software interface is easy to use and the high light sensitivity allows me to get images with with little motion blur.

> Brian Fisher, Carnegie Mellon University USA

We use two synchronized Photron SA2 cameras to record predatory flights. which last as little as 1/4 of a second. In the field the temperatures reach 35 degrees (Celsius) with 98% humidity and the animals are free to fly away at any point. It is challenging and intensive work but we found the reliability of the hardware under such conditions to be outstanding. We are also limited, and features that have increased the number of successful trials recorded include being able to use any of our lenses and recording at low light by using IR light (which is detected by the camera sensor but not by the animals). The ease of use means that anyone in our team can set them up quickly. Crucially, we found the software to be flexible, intuitive and always reliable, with functions that greatly improved our efficiency.

> Paloma Gonzalez-Bellido, Lecturer in Physiology, University of Cambridge

Reamda Ltd designs and manufactures bomb disposal robots. The primary tool used by the robot is a device called a Disrupter Cannon, it’s basically a ballistic water cannon with large recoil forces up to 34 kN.

To protect the robot from these forces we needed to design special dampening systems to absorb the recoil, however because the entire firing operation is over in a few milliseconds we usually can only examine the aftermath to ascertain where improvements can be made.

What we needed was a way to watch the entire firing process in slow motion so we could see where stress points were, after some research we made contact with Photron UK, they were able to provide us with examples of similar ballistic testing and very quickly came up with a camera specification that would meet our needs.

Another point worth mentioning is the ballistic windows in our test facility are 58mm thick which causes significant attenuation in the light levels being recorded but Photron assured us that if we could see it the camera would see it and that was exactly the result we achieved.

Disruptor ammunition is quite expensive and it took 3 years and 600 rounds to design our current dampening system, I’ve no doubt that the detailed analysis we get from the high speed footage will significantly reduce this time going forward.

In summary I would like to say that Photron UK really know their product and pass that knowledge to their customers with clear and intuitive instructions and I would have no hesitation in recommending them.

> Padraig O’Connor – Managing Director, Reamda Ltd.