Microfluidics

MICROFLUIDICS

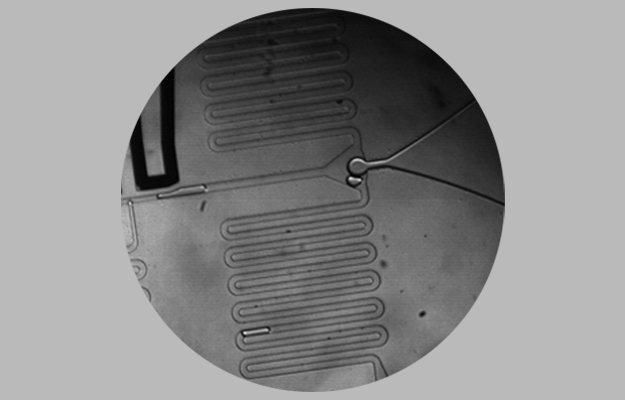

Microfluidics is the science of manipulating and controlling fluids through micro-channels. This type of research requires microminiaturized devices that contain chambers through which fluids flow or are confined. A microfluidic chip enables fluids, down to femtoliters (fL), to be transported, mixed, separated, processed or visualized. Fluids behave differently on a micrometric scale than they do in a normal environment, these unique behaviors are important for scientific research and detailed experiments.

For years, high-speed imaging has been utilized in the following industries for microfluidics research and analysis: Academia, Medical, Biotechnology, Energy, Chemistry, Biology, Pharmaceuticals and more. High-speed cameras have the ability to capture large amounts of data for slow motion analysis.

High speed imaging of micro-sized droplet jetted on surface with wettability pattern

Continuous-wave laser generated jets for needle free applications

Contactless Boiling: A way to improve the reliability of microfluidics process?

Read more. (page 29)