Research & Development

R&D

New product design and development is a crucial factor in the success of any organization. The utilization of new and innovative materials and processes requires a complete understanding of events that are too fast for the eye to see. High-speed imaging allows engineers and scientists to visualize, measure and characterize complex industrial processes and experimental scientific research.

For years high-speed imaging has been used by research and development teams worldwide providing engineers and manufactures with detailed analysis of a wide variety of events. Common applications and techniques in the R&D field include, but are not limited to, the use of Digital Image Correlation (DIC), Materials Testing, Production Line Troubleshooting, Robotics, and more. To learn more about each application and technique or to find out what type of Photron high-speed camera would be best suited for those applications simply click on the title for each section.

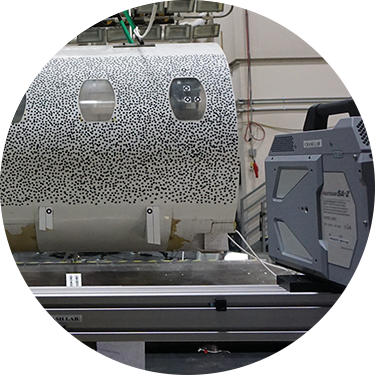

Digital Image Correlation – Digital Image Correlation, often referred to as DIC, is a 2D or 3D optical tracking technique used to measure deformation, vibration and strain in materials. DIC tracks a gray value pattern in subsets through digital imaging. You will often see this speckled pattern on objects such as aluminum, rubber, glass, and plastics. This technique is used for a variety of tests including torsion, tinsel, bending, or load testing. DIC can be used on very small or large testing areas.

Materials Testing – Organizations and consumers place their trust in various materials every day. Throughout every major industry, engineers need to be assured that the materials used in manufacturing their products or equipment are up to their intended task. Therefore, they must actively and diligently verify that the manufacturing processes will perform to expectations. Materials testing is a highly precise technique that measures the characteristics of materials, such as mechanical properties, elemental composition, corrosion resistance and the effects of heat treatments. Most testing is performed on metallic materials, composites, ceramics and polymers.

High-speed imaging is applied to materials testing in order to measure the physical and mechanical properties of different materials or components. Typical testing methods include: Tensile Testing, Drop Testing, Compression, Deformation, Crush Resistance, Delamination and many more.

Production Line Troubleshooting – Using high-speed cameras for production line troubleshooting and monitoring has been an essential tool used by manufacturing, engineering, and quality personnel worldwide. They are used to verify and document periodic issues, including timing, failure, and equipment performance issues to expedite process improvement and drive corrective action. When using high-speed cameras to troubleshoot industrial machinery and manufacturing equipment, you virtually stop the process allowing the catastrophic flaw to be visualized.

Robotics – A high-speed camera can be an essential tool when it comes to testing, measuring, calibrating, and debugging robot mechanisms.

APPLICATIONS & TECHNIQUES

MATERIALS TESTING

DIGITAL IMAGE CORRELATION

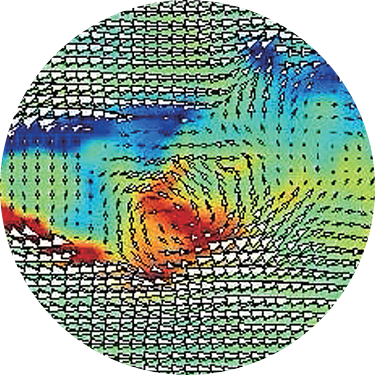

PARTICLE IMAGE VELOCEMTRY

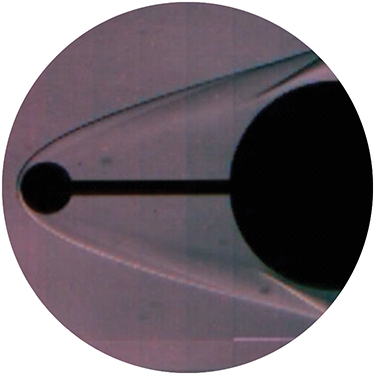

SCHILIEREN

Conditional sampling analysis of high-speed schlieren movies of Mach wave radiation in a supersonic jet

Acoustic-triggered conditional sampling analysis can extract the broadband-noise-related intermittent fluctuations from complicated schlieren visualization movies around the source region, which is difficult when using conventional methods. In this study, an analysis of the Mach wave radiation from a supersonic jet was performed. The extracted results properly captured the known features of the Mach waves and their sources (i.e., wavepacket at the jet boundary) and clearly showed the correlation between these near-field fluctuations and the far-field intermittent acoustic events. This analysis can potentially be applied to other broadband, intermittent turbulent noise and will provide a better understanding of their generation mechanisms.

Smartphone background-oriented schlieren for locating gas-leak source in emergencies

We propose a smartphone background-oriented schlieren (SBOS) technique, which is inexpensive, and easy to implement for gas-leak detection due to density field variations in the air. Traditional gas-leak detectors are often designed to measures point-wise concentration in the gas-filled space and thus not suitable for immediate location of leak source. SBOS is proposed as an alternative method for gas-leakage detection safely and quickly since SBOS optically measures the density changes without direct non-contact. The smartphone as a portable gas leak detector has significant advantages compared to the high-speed camera often used in laboratory research since it is inexpensive and portable. We apply SBOS to measure the density gradient field of the air around a flame and helium gas jetting from a nozzle at high-pressure. In order to detect the density gradient by SBOS, we use only a smartphone as BOS camera, a room lamp as light source and a color background. In the analysis we use the coloredcross-correlation method which reduces noises of displacement fields.

Read more

Induction of highly dynamic shock waves in machining processes with multiple loads and short tool impacts

Modeling and simulation for an optimized design of a dynamic bending test

Performance prediction of fibre-reinforced concrete structures under impact is of major importance in a wide range of industrial applications. Therefore,the study of the dynamic behaviour of the material is necessary to quantify the dynamic mechanical properties of the material in terms of both mechanical response and fracture behaviour: dynamic fracture energy and tensile strength. This study aims to design a modified Hopkinson bar bending test with a series of numerical simulations prior to the actual test in order to select a feasible experiment configuration. Results of a dynamic bending experiment on a steel fibre-reinforced concrete specimen loaded up to failure are presented.