Schlieren

SCHLIEREN

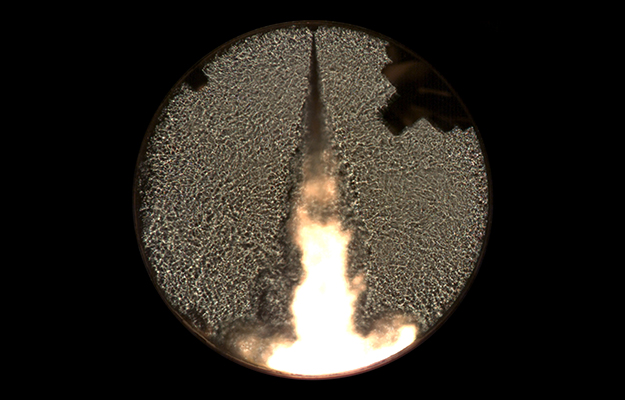

Schlieren imaging is used as a means of visualizing changes in pressure, temperature and shock waves in a transparent medium such as air. In applications such as wind-tunnels and pressure chambers schlieren imaging provides clear and detailed information on changes of pressure and density.

Schlieren imaging was developed in the 1800’s to detect flaws or ‘schliere’ in glass. The technique is frequently used today as a means of visualizing shock waves in wind-tunnels and temperature gradients around objects. Schlieren imaging relies on the refractive index, the ability to ‘bend’ light, of a transparent medium changing with density to produce an image. In a simple schlieren system a parallel beam of light is passed through the subject and is focused on to a knife edge using lenses or spherical mirrors. A change in density in part of the subject causes that part of the light beam to be refracted and to fall above or below the knife edge creating lighter or darker areas in the image. Color filters are sometimes used in place of a knife edge to produce an image using different colors to denote different areas of density.

Optical Set up – Illumination for schlieren imaging must be produced from a point light source. For high speed photography the intensity of the light source and sensitivity of the imager should allow recording at the desired frame rate. A parallel beam of light is created using a pair of lenses or mirrors. The diameter of the lenses or mirrors determines the size of the working area, or measurement volume, in which the image is produced. A knife edge or specially designed color filter is mounted on a Vernier adjustment close to the image plane. The schematic diagram above shows the light path and position of the camera sensor.

Optical-flow-based background-oriented schlieren technique for measuring a laser-induced underwater shock wave

Read more

Visualization of the aerodynamic vortices by Background Oriented Schlieren

Read more

Whole-field optical measurements of sound wave propagation from high-speed exhaust jets

Read more